LED PCB assembly

-

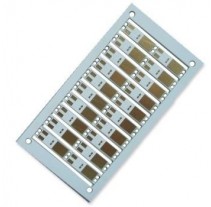

One-stop Aluminum PCBA factory

Product type: Aluminum Substrate board

Material: Aluminum plate +high thermal insulation material …

One-stop Aluminum PCBA factory

Product type: Aluminum Substrate board

Material: Aluminum plate +high thermal insulation material …

-

shenzhen Aluminum PCB assembly with LED...

Product type:aluminum pcb assembly

Material: aluminum material

Layer/Thickness: 1L/1.6mm

Outer…

shenzhen Aluminum PCB assembly with LED...

Product type:aluminum pcb assembly

Material: aluminum material

Layer/Thickness: 1L/1.6mm

Outer…

-

Metal backed PCB Assembly made in China

Layer NO# 1 or 2Layers

Unit Size: As gerber files

Panel Size: As gerber files

Units in Pane…

Metal backed PCB Assembly made in China

Layer NO# 1 or 2Layers

Unit Size: As gerber files

Panel Size: As gerber files

Units in Pane…

-

high tension Aluminum PCB for led

Product type: high tension aluminum pcb for led

Material: Aluminum plate +high thermal insulation m…

high tension Aluminum PCB for led

Product type: high tension aluminum pcb for led

Material: Aluminum plate +high thermal insulation m…

-

Shenzhen custom Aluminum PCB design LED...

Material: Aluminum Bases

Layer/Thickness: 2L/1.6 mm

Copper Thickness:1 OZ

Surface treatment…

Shenzhen custom Aluminum PCB design LED...

Material: Aluminum Bases

Layer/Thickness: 2L/1.6 mm

Copper Thickness:1 OZ

Surface treatment…

-

LED pcb assembly with bulb

Layer NO# 1 Layer

Unit Size: As gerber files

Panel Size: As gerber files

Units in Panel 1

…

LED pcb assembly with bulb

Layer NO# 1 Layer

Unit Size: As gerber files

Panel Size: As gerber files

Units in Panel 1

…

-

Metal Core PCB Assembly in China

Metal core PCB assembly

Material: Metal core +high thermal insulation material

Layer/Thickne…

Metal Core PCB Assembly in China

Metal core PCB assembly

Material: Metal core +high thermal insulation material

Layer/Thickne…

LED Printed Circuit Board Assembly - Your One-Stop Shop for LED Lighting PCBs

Welcome to our LED board assembly space specializes in printed circuits. With over 10 years of experience manufacturing high-quality LED lighting assemblies, we are your trusted partner for all your custom board needs.

Aluminum PCB Assembly for Efficient LED Lighting

They are the preferred choice for lighting applications due to aluminum's high thermal conductivity. We specialize in precision aluminum LED PCB assembly utilizing state-of-the-art equipment for quality and consistency.

- 1.5-3.8 W/m.k aluminum material

- 1.0mm - 1.6mm thickness

- 1 oz copper thickness

- ENIG, Immersion Gold, Immersion Silver surface finishes

Applications of Printed Circuit Board

PCB plays a pivotal role in shaping the modern world. More than just a platform for electronic components, it's the nerve center of countless devices, silently orchestrating their functions.

Let's delve into the diverse applications of these miniature marvels:

1. Consumer Electronics: They are omnipresent, from smartphones in our pockets to TVs adorning our walls. They power the intricate workings of laptops, gaming consoles, cameras, and more, enabling seamless connections, vivid displays, and powerful processing.

2. Medical Devices: PCB Board Assembly are crucial in modern healthcare, powering life-saving equipment like pacemakers, defibrillators, and diagnostic tools. Their compact size and precise functionality enable the miniaturization of devices, improving patient comfort and portability.

3. Industrial Automation: In factories and production lines, they control robotic arms, manage conveyor belts, and monitor complex processes. Their durability and reliability ensure smooth operation and efficient production in harsh environments.

4. Automotive Technology: Modern cars are brimming with that controls everything from engine management and fuel injection to safety features like airbags and anti-lock brakes. Their ability to withstand vibrations and temperature extremes makes them ideal for automotive applications.

5. Aerospace and Defense: From satellites orbiting Earth to drones soaring through the skies, they are essential for navigation, communication, and mission-critical operations.

Their high-performance capabilities and resilience ensure accuracy and reliability in demanding aerospace and defense scenarios.

Get a quote and order today for your industrial needs!

Why Choose Us?

When you choose us for PCB assembling board-related requirements, We will gladly help you with all the following:

Quick Turnaround Prototype and Production

We understand the urgency required for LED lighting projects. Our rapid prototyping services provide fully functioning concept models for 1-2 layer aluminum boards with a 5-day turnaround.

For production, we have the capacity for high-volume orders with 2-week delivery on 1-2 layers up to 600mm x 1200mm panels.

One-stop service for All Your PCB Needs

From PCB fabrication to Component Procurement to assembly. We provide complete end-to-end manufacturing capabilities for faster time-to-market. Our one-stop LED PCB production and assembly services include:

- Prototype and production volume PCB fabrication

- Sourcing of all electronic components and LEDs

- SMT Pick-and-place assembly

- Reflow soldering

- Final testing and inspection

High-Quality Components for Optimal LED Performance

We source high-quality electronic components from industry-leading brands, including OSRAM, Cree, and Lumileds, to complement our LED PCB Assembly. Using brand-name LEDs and proven reliable components ensures long-lasting and energy-efficient performance of your lighting product designs. Our quality control team carefully inspects and tests all assemblies before shipment.

Engineering Support for Seamless Manufacturing

Our engineering team provides start-to-finish support for your overall project success through the following:

- Gerber file reviews

- Design for manufacturing (DFM) audits

- Component selection recommendations

- Assembly process reviews,

- Product testing and evaluation

With expertise across mechanical, electrical, quality, and manufacturing engineering, we identify and resolve any potential issues early for smooth production.

Get Your Quote Today!

With over 10 years of supporting LED lighting customers worldwide, we have the knowledge and capabilities to manufacture your custom boards. For a fast quote on prototype or production volumes, contact us at (+86-755-29970700) or sales@hitechcircuits.com

FAQs

1. What types of materials do you use for your LED PCB assemblies?

We utilize high-quality aluminum and FR4 materials. We use 1.5-3.8 W/m.k aluminum alloy plates with 1 oz copper, and your choice of ENIG, Immersion Gold, or Immersion Silver surface finishes for applications requiring thermal dissipation. For cost-sensitive applications, we offer standard 1.6mm thick FR4 boards.

2. What are the size options available for your circuit board assemblies?

We manufacture circuit board assemblies in sizes ranging from compact 20mm x 20mm boards to large 600mm x 1900mm panels. Our SMT lines support boards up to 510mm x 510mm. For exceptionally large or custom-sized boards, please reach out for further details.

3. How long does manufacturing a prototype usually take?

For simple 2-layer prototypes, our standard lead time is 5 days from Gerber file approval to fully functioning assembled boards using LCSC in-stock components. Prototypes can be completed within 2-3 weeks for more complex designs with sourced components.

4. What testing and inspections do you perform?

100% of our assembled ones undergo automated optical inspection (AOI) and multi-point testing of all functions. Our engineers carefully verify component placement, solder joint quality, and LED illumination performance to catch any defects before shipment.

5. What surface finishes do you offer?

Our common surface finish options are ENIG (Electroless Nickel Immersion Gold), Silver, Immersion Tin, and HASL (Hot Air Solder Leveling). We can recommend the best finish for your application based on solderability, reflectivity, and durability requirements.

6. Are PCB and PWB different?

Yes, a printed circuit board (PCB) is fully assembled with all the electronic components and circuitry required for an electronic device to function.

In contrast, a printed wiring board (PWB) is a bare board that only contains the interconnecting wires and pads to mount components without any installed electronics. The PWB is the foundation upon which a functional PCB is constructed once all necessary components have populated the board.