Ceramic Printed Circuit Board VS Metal Core PCB

Ceramic Printed circuit board and Metal Core PCB are good in heat dissipation of PCB board.The application of the traditional LED heat dissipation substrate, Metal Core PCB (MCPCB) is different from the application range of ceramic heat dissipation substrate.MCPCB is mainly used in the system circuit board.The ceramic circuit board is applied to the LED chip substrate.However, with the evolution of LED requirements, the two are gradually applied to the process of COB (Chip on board).The following we will discuss and compare the two material.

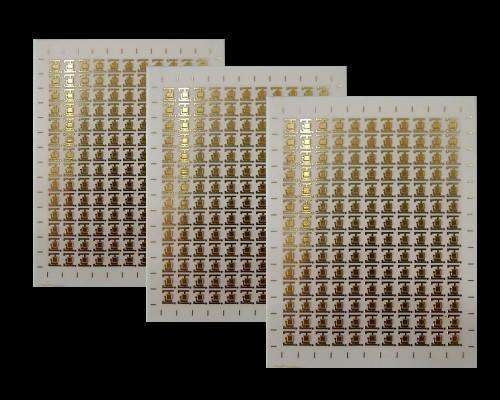

The ceramic printed circuit board is a kind of heat conducting ceramic powder and organic binder, and the heat conduction organic ceramic circuit board is prepared at a thermal conductivity of 9-20W/m.k under the condition of less than 250.The ceramic circuit board is an ideal packaging material for the new generation of large scale integrated circuits and power electronic modules with high thermal conductivity, good chemical stability and excellent thermal stability.In the near future, there are many ceramic printed circuit boards are used in high power LED heat dissipation substrates.However, LTCC / HTCC use thick film technology to prepare metal lines, making line accuracy is not very high, and limited by process factors, it is not adapt small size PCB.Therefore, the process capability of LTCC / HTCC is not suitable for small size and high power products at present.On the other hand, DBC is also limited to technological capability, and line resolution is only suitable for 100~300um.And its capacity for mass production is limited by the air hole in the metal / ceramic interface. Consider ceramic circuit board line accuracy, material heat dissipation coefficient, metal surface evenness and metal / ceramic indirect overlap,The most widely applied category of DPC ceramic substrate is made of thin film micro film at present.Ceramic Printed circuit board.

MCPCB is mainly evolved from the early copper foil printed circuit board (FR4).MCPCB takes the metal as the core technology, uses aluminum or copper metal as the substrate of the printed circuit board, and attaches a copper foil or copper plate on the substrate to improve the heat dissipation.Due to the good ductility and heat conduction of the aluminum metal itself and the high thermal conductivity of the copper metal, MCPCB is reasonable to have a very good heat conduction / heat dissipation effect.However, aluminum itself is a conductor,based on the product characteristics, an insulator must be insulated between aluminum substrate and copper to avoid the conduction of copper line and aluminum substrate.Therefore, MCPCB mostly uses polymer materials as insulating material, but the thermal conductivity of the insulating layer (Polymer) is only 0.2~0.5W/mK, and there is a problem of heat resistance.Therefore, the thermal conductivity of the aluminum / copper metal, which has excellent thermal conductivity, is formed after the addition of Polymer, which greatly reduces the heat conduction efficiency of the whole substrate,lead to thermal conductivity of MCPCB is only 1W/mK~4W/mK.In recent studies, high conductive materials were cladded to MCPCB polymer materials, although the thermal conductivity of MCPCB products was raised.But the thermal conductivity of the main axis of the MCPCB is only about 3~5W/mK,However, in practical application, MCPCB also faces metal extension due to the Stamping Division.At this time, the deformation of the metal copper layer is caused by the extension of the stamping deformation, which leads to the deformation of the polymer dielectric insulating layer at the edge of MCPCB,In this way, it is easy to make the pressure resistance of LED products unstable (dielectric polymer deformation and damage).