Ceramic PCB

-

Aln Ceramic PCB Circuit Board

Aln Ceramic PCB Circuit Board

Material: Ceramic ALN

Unit size/mm: 72.8*24 &nb…

Aln Ceramic PCB Circuit Board

Aln Ceramic PCB Circuit Board

Material: Ceramic ALN

Unit size/mm: 72.8*24 &nb…

-

Aluminum Nitride & Alumina Ceramic Substrates...

Aluminum Nitride & Alumina Ceramic Substrates Printed Circuit Board

Material: Ceramic …

Aluminum Nitride & Alumina Ceramic Substrates...

Aluminum Nitride & Alumina Ceramic Substrates Printed Circuit Board

Material: Ceramic …

-

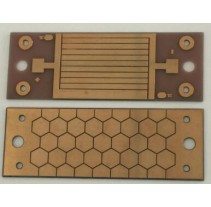

Aluminium Nitride PCB for Printer

China Aluminium Nitride PCB factory

Board Material: Aluminium Nitride (ALN) . &n…

Aluminium Nitride PCB for Printer

China Aluminium Nitride PCB factory

Board Material: Aluminium Nitride (ALN) . &n…

-

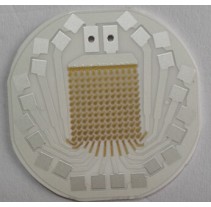

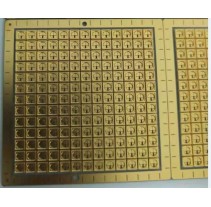

Alumina Ceramic PCB for Semi-Conductor

Alumina Ceramic PCB from China

PN: SUB0005 RD

Alumina Ceramic material

0.63mm…

Alumina Ceramic PCB for Semi-Conductor

Alumina Ceramic PCB from China

PN: SUB0005 RD

Alumina Ceramic material

0.63mm…

-

0.63mm Alumina Ceramic PCB for Printer

Alumina Ceramic PCB from China

Alumina Ceramic material

0.63mm board thickness

…

0.63mm Alumina Ceramic PCB for Printer

Alumina Ceramic PCB from China

Alumina Ceramic material

0.63mm board thickness

…

-

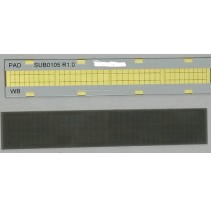

Aluminium Nitride (ALN) PCB

Aluminium Nitride (ALN) PCB

PN: SUB0105 R1.0

Aluminum Nitride (ALN) material

0.5mm C…

Aluminium Nitride (ALN) PCB

Aluminium Nitride (ALN) PCB

PN: SUB0105 R1.0

Aluminum Nitride (ALN) material

0.5mm C…

-

Aluminium Nitride Ceramic PCB Board

Aluminium Nitride Ceramic PCB Thermal Conductivity

High ceramic PCB thermal conductivity …

Aluminium Nitride Ceramic PCB Board

Aluminium Nitride Ceramic PCB Thermal Conductivity

High ceramic PCB thermal conductivity …

-

Multilayer Ceramic PCB printed circuit board

We can build multilayer Ceramic PCB, up to 30 layers.

Ceramic PCB includes&…

Multilayer Ceramic PCB printed circuit board

We can build multilayer Ceramic PCB, up to 30 layers.

Ceramic PCB includes&…

-

Ceramic PCB Manufacturer, Ceramic Substrate...

Hitech Circuits Co., Ltd. is a leading Ceramic PCB Manufacturer and Ceramic Substrate Manufacture…

Ceramic PCB Manufacturer, Ceramic Substrate...

Hitech Circuits Co., Ltd. is a leading Ceramic PCB Manufacturer and Ceramic Substrate Manufacture…

Hitech Circuits: Your Ceramic PCB Partner

Many users of printed circuit boards find ceramic Circuit Boards advantageous over traditional boards of other materials. This is because they provide suitable substrates for electronic circuits with high thermal conductivity and a low expansion coefficient (CTE). The multilayer ceramic PCB is extremely versatile and can replace a complete traditional printed circuit board with a less complex design and increased performance. You can use them for high-power circuits, chip-on-board modules, proximity sensors, and more.

We provide specialized ceramic printed circuit board (PCB) solutions for companies needing high-reliability boards. With over 10 years of experience designing and fabricating ceramic substrates, we are an industry-leading supplier in China committed to quality, service, and technical expertise.

What are Ceramic PCBs?

Ceramic printed circuit boards (PCBs) provide a substrate made of ceramic material rather than the traditional fiberglass for the circuits. Common ceramic materials include aluminum oxide, aluminum nitride, beryllium oxide, and silicon carbide. Ceramic PCBs offer higher heat resistance, superior thermal conductivity, lower expansion coefficient, better high-frequency performance, and smaller package sizes than traditional PCBs.

Benefits of Using Our Ceramic PCBs and Ceramic Substrate PCB!

Several key benefits make Ceramic Substrate PCB and ceramic based PCBs an advantageous choice:

- Higher Operating Temperatures - Can withstand temperatures exceeding 350°C.

- Enhanced Thermal Properties - Aluminum nitride boards provide thermal conductivity exceeding 150W/mK.

- Lower Expansion Coefficient - More stable performance across temperature changes.

- Compact Form Factor - Allows greater component density and miniaturization.

- Superior High-Frequency Performance - Low dielectric loss for high-frequency operation.

- Hermetic Packaging - Prevents moisture absorption issues.

- Lower System Costs - Simpler designs can reduce testing/assembly costs.Benefits of Using Our Ceramic Circuit Boards and Ceramic Substrate PCB!

With their exceptional thermal conductivity, electrical insulation properties, and high heat and corrosion resistance, ceramic PCBs outperform conventional PCBs in demanding applications.

Applications of Ceramic Printed Circuit Boards

Some of the top applications that benefit from utilizing Ceramic Printed Circuit Board technology include:

- Aerospace Electronics - Reliability in extreme environments

- Automotive Systems - Withstand high temps in engine compartments

- Industrial Equipment - Heavy machinery and high power devices

- Medical Instruments - Precision components in medical devices

Ceramic substrates are also increasingly being used for modules and chip-on-board assemblies to replace entire PCBs. Examples include electric vehicle battery controllers, high-power LED modules, DC-DC converters, and solid-state relays.

The Structure and Composition of Our Ceramic PCBs

Ceramic based PCBs consist of the following components:

- Ceramic Material: Most commonly aluminum oxide, aluminum nitride or beryllium oxide

- Conductors: Typically silver palladium or gold palladium

- Maximum Use Temperatures: Can operate from -55°C up to +850°C

- Thermal Conductivity: Ranges from 20W/mK to over 200W/mK

- Breakdown Voltage: 15-28KV/mm

Advanced Ceramic PCB Technology

New developments in material science and fabrication methods have made our ceramic PCBs and Ceramic Substrate board more practical and cost-effective. Some leading innovations include

- Direct Copper Bonding - For improved thermal performance.

- Active Metal Brazing - This enables complex multilayer designs.

- Thin Film Technologies - Allow precision circuit patterns

These technologies enable smaller, lighter, and better-performing ceramic PCB designs tailored to demanding applications.

Partnering With The Best Ceramic PCB Manufacturers!

With over 10 years of experience as a ceramic printed circuit board (PCB) technology specialist, Hitech Circuits offers unparalleled capabilities for designing and manufacturing high-reliability, high-performance ceramic boards and substrates.

In-House Engineering and Testing

Our experienced engineering team provides comprehensive support, including

- Material Selection Consulting,

- Thermal Analysis

- Mechanical Modeling,

- Design Optimization,

- Prototyping Services

- Rigorous Testing, and Qualification.

Trust our expertise in Ceramic Circuit Board engineering to deliver optimal, ruggedized PCB solutions.

Advanced Ceramic PCB Fabrication

We utilize cutting-edge ceramic PCB processes for precision fabrication:

- Direct Copper Bonded (DCB) Ceramics

- Active Metal Brazing (AMB) Multilayering

- Thin/Thick Film Technologies

- Laser Trimming and Drilling

Our advanced capabilities enable smaller sizes and finer lines/spaces versus standard processes.

Complex Multilayer Constructions

Achieve greater functionality integration with our complex ceramic multilayering ability - up to 30 layers are accommodated!

Quick-Turn

Prototypes and Production

Meet tight deadlines for prototypes and scale smoothly to volume production. We provide flexible order sizes even for low quantities.

Contact Hitech Circuits Today!

We offer competitive pricing across all our premium ceramic PCB or Ceramic Substrate PCB services. Get in touch to discuss your specific project requirements!

FAQs

1. What are the main benefits of using a ceramic PCB?

Some major benefits include higher heat tolerance, better thermal conductivity, tight expansion coefficients for reliability, superior high-frequency performance, and the ability to create smaller/denser packages.

2. What industries typically use ceramic Circuit Board?

Key industries that leverage ceramic PCB technology include aerospace, automotive, telecommunications, industrial equipment, medical devices, and military/defense. Their performance advantages meet the demands of these environments.

3. How do ceramic PCBs differ from traditional PCBs?

Unlike standard glass-epoxy PCBs, ceramic boards use a ceramic material substrate that can withstand temperatures exceeding 850°C. They have higher thermal conductivity for better heat dissipation, tighter expansion coefficients for reliability under temperature shifts, and low dielectric loss, enabling high-frequency operation.

4. Does Hitech Circuits offer prototyping services for ceramic PCBs?

Yes, we provide quick-turn ceramic PCB prototyping to help test concepts and validate designs before volume production. We can deliver prototypes in just a few weeks!

5. What advanced ceramic PCB capabilities do Hitech Circuits have?

We utilize cutting-edge techniques like direct copper bonded (DCB) ceramics, active metal brazing multilayering, thin/thick film technologies, and laser micromachining. These processes enable smaller, higher-performing designs that are not achievable with standard methods.

6. How can I get a custom ceramic PCB order quote?

Contact a Hitech Circuits representative at +86-755-29970700 or email us your details at sales@hitechcircuits.com with details on your ceramic PCB specifications, quantity needs, and other requirements. We're happy to provide free quotes for any project! Let us know how we can help.